Custom-made solutions for greater wellbeing

R82 has been producing aids for children and young people with special needs since 1982. For children, youngsters and adults who need more support than a standard product can give them, R82 has for more than 20 years been able to provide them with a custom-made seat or a Turtle seat as we call them at R82.

Our entire Turtle product range is built on the ambition to make life easier for our users by bringing their upper body into balance and make sure that the mould relieve pressure from the spine, while avioding stressing or overloading the pelvis in any way.

A unique solution for every user

Every moulded unit is designed and produced after careful consideration of the needs and experience of the individual user. Our solutions can be combined to fit every needs of the user. They can consist of a moulded seat or just the back rest.

At R82 we have a huge repertoire of solutions that let us accommodate any need. Our long list of head rests, foot supports, arm rests and other accessories can all be combined with any moulded Turtle unit. No matter what needs the user has, we are always prepared to meet them.

Custom-made solutions: The process behind the moulded seat

At R82 you are in safe hands

For many years our high qualified R82 specialists, have worked closely together with the moulded solution advisers.

1. Shaped to the body

2. Fine adjustments

3. Complete 3D scan

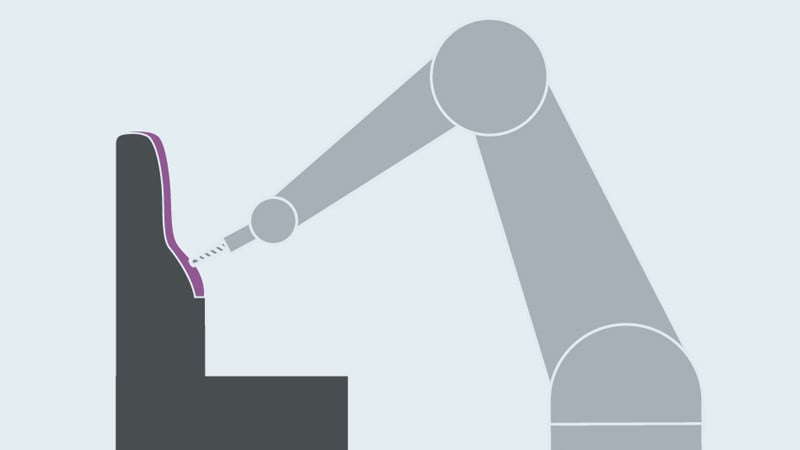

4. Robot precision

5. Final adjustments